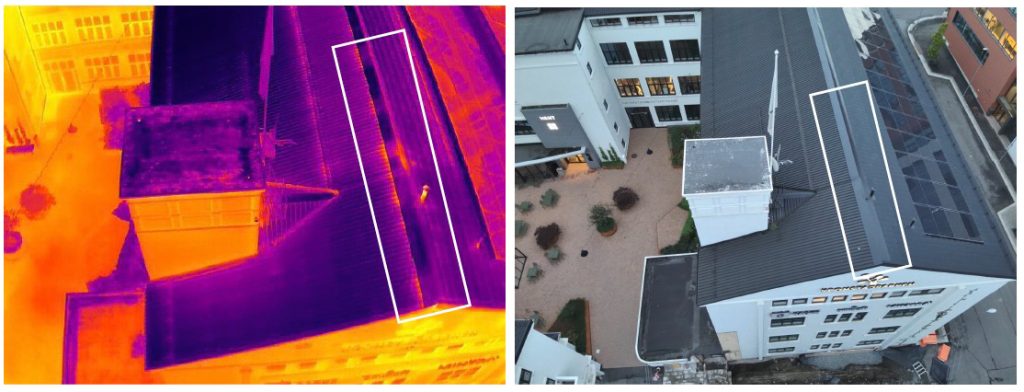

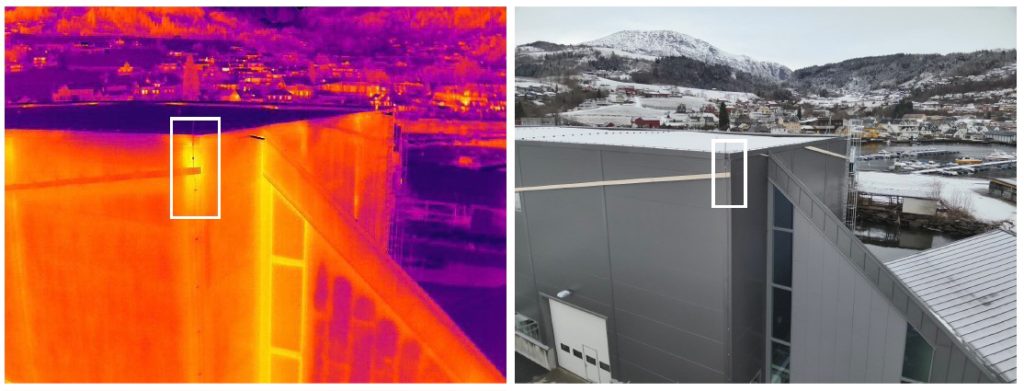

We perform advanced inspections using high-resolution photography, thermal imaging, and 3D modeling technology.

We perform advanced drone-based inspections using high-resolution photography, thermal imaging, and 3D modeling.

This enables us to identify heat loss, moisture intrusion, corrosion, structural changes, and loose façade systems with fall risk – long before damage becomes visible or costly.

Unlike traditional methods, our approach combines thermal and visual data with engineering evaluation. Each inspection is analysed by certified engineers who interpret and verify findings, ensuring accuracy and relevance.

We inspect

Our inspection services cover a wide range of assets and structures

We perform advanced drone-based inspections using high-resolution photography, thermal imaging, and 3D modeling.

This enables the early detection of heat loss, moisture intrusion, corrosion, structural changes, and loose facade elements with fall risk, long before damage becomes visible or costly.

Unlike traditional methods, we combine thermal and visual data with engineering expertise. Each inspection is reviewed and verified by certified engineers who interpret the findings, ensuring high accuracy and reliability.

View a sample report here (opens a PDF in a new window. Right-click and select “Save as” to download).

View a presentation of our inspection services here (opens a PDF in a new window. Right-click and select “Save as” to download).

Our inspection services cover, among other areas, the following:

- Buildings and façades

- Industrial facilities and infrastructure

- Telephone and transmission towers

- Solar panels and renewable energy installations

- Wind turbines and offshore structures

- Cranes, lifting equipment, and steel frameworks

- Ships, terminals, and port facilities

- Bridges, tunnels, and large civil constructions.

Inspection images overview

Click images below to enlarge

Our technology detects:

- Corrosion, cracks, and structural deformation

- Moisture and water ingress

- Heat and energy leakage (thermal bridges, insulation faults)

- Loose façade elements or glass panels that pose a fall hazard

- Air leakage, material fatigue, and delamination in steel or composites

Measurable insight and sustainability

Thermal data is converted into measurable energy loss, expressed in kWh, CO₂, and financial value, providing a clear link between technical condition and operational performance.

A typical inspection can uncover savings potential of 20,000–35,000 kWh per year, while producing less than 1 kg CO₂ – over 95% less than traditional methods.

Each report documents both technical findings and environmental impact, helping property owners make informed, climate-positive decisions.

Drone-in-a-box solution

For clients requiring continuous or automated inspections, we offer the KTV Care Dock Solution – a “drone-in-a-box” system enabling remote inspection, site security, and area monitoring.

The dock allows scheduled or on-demand flights without manual deployment, ideal for large industrial areas, ports, or offshore assets.

Contact us for more information or a tailored Dock setup for your facility.

Integrated with

Through our long-term maintenance agreements, we ensure façades and windows remain clean and documented through regular inspections and reports.

Every three years a new inspection is carried out, with results available in the Bluetag Quality System, providing full transparency on condition, history, and required actions.

Combining inspection with cleaning and surface treatment reduces total cost and ensures complete control over asset maintenance.

Why choose KTV Care

No building or structure is maintenance-free. Ignoring inspection leads to hidden degradation and higher lifecycle costs.

With the KTV Care agreement, we take full responsibility for ensuring that facades and windows remain clean through a long-term maintenance plan. In addition, every three years an inspection is carried out along with a condition report.

Clients receive access to the Bluetag quality system portal, where they can easily view the full history of completed work and inspection reports. This agreement provides full oversight of external damage and future maintenance needs.

All reports are prepared by structural engineers and focus on building damage, thermal leaks, cracks, water ingress, and general needs for cleaning or surface treatment.

By combining cleaning and inspection, costs are significantly reduced for the client while ensuring complete control over the building’s maintenance.

KTV Care delivers verified, measurable insight, fewer uncertainties, reduced risk, and improved sustainability across your assets.

Sustainability

Our technology is designed to remove personnel from hazardous work environments, eliminating the need for scaffolding and aerial lifts. In most cases, the total time required for operations is significantly reduced.

We’ve also developed the KTV PowerCleaner, a high-pressure washer powered entirely by battery, making it 100% electric. This machine is unique in it’s class and features a pure water system that minimizes the need for chemicals, reducing environmental impact.

Digital compliance & documentation

Our Bluetag CRM system is fully compliant with ISO 14001, ISO 45001, and ISO 9001 standards.

All jobs and projects are documented with checklists, risk assessments, reports, and images.

This documentation is available online to clients from the very start of the project, ensuring transparency, traceability and quality control at every stage.

Get a quote now!

KTV Working Drone delivers a comprehensive range of services, including facade and window cleaning, solar panel cleaning, infrastructure maintenance and cleaning, maintenance agreements as well as drone based inspections and 3D mapping.

Our drone technology removes the need for hazardous work methods, specialized access techniques, and complex safety procedures.

Please, feel free to send us a non-binding inquiry.