Services

Energy sector

Comprehensive drone solutions for the energy sector

Maintaining energy infrastructure is critical to ensuring reliable performance, safety, and long-term value. Traditional maintenance methods often involve high costs, significant safety risks, and time-consuming procedures.

At KTV Working Drone, we offer cutting edge, drone based solutions specifically designed for the energy industry, covering wind turbines, solar panels, and hydropower structures. Our approach eliminates the need for dangerous manual work while improving efficiency, reducing environmental impact, and cutting maintenance costs.

Since 1992, we have built solid experience in cleaning and surface treatment. With drone systems developed in Norway, we combine deep industry knowledge with innovative technology to deliver safe, sustainable, and high-precision maintenance services.

Wind turbines, dams, and solar panels require regular cleaning, inspection, and surface treatment.

KTV Working Drone offers a range of solutions that ensure proper maintenance, without putting personnel at risk.

Safe, smart and proven services and technology for the energy sector

Wind turbines

KTV Working Drone can carry out both cleaning and surface treatment of wind turbines. As part of our development program, we have engineered a nano-coating that significantly reduces the need for frequent cleaning. In addition, the coating prevents ice formation on turbine blades during winter, which improves energy production and reduces the risk of ice throw by up to 95%.

The same treatment also minimizes blade damage caused by ice buildup.

We provide a complete solution that includes cleaning, surface treatment, and detailed inspection of wind turbines, optimizing performance and safety.

Solar panel

Keeping solar panels clean is essential to maintaining peak energy output. We recommend a minimum of 1-2 cleanings per year. Without regular cleaning, dirt and debris can lead to long-term damage and a significant reduction in electricity production.

Our drone systems use pure water technology with zero physical contact, making this the most sustainable and non invasive method of solar panel maintenance.

Post cleaning, we conduct thorough inspections and provide damage reports to ensure optimal performance and longevity.

Hydropower structures

Concrete infrastructure, especially at dams and water retention systems, must be regularly inspected for cracks, wear, and water ingress. Our drones can perform high-pressure cleaning with hot water up to 300 bar, delivering deep cleaning of concrete surfaces.

After cleaning, our drones perform visual and thermal inspections. The collected data is then analyzed by our engineers, who produce comprehensive reports on structural condition and potential damage.

Surface treatment

Using drones, we can efficiently apply impregnation products and nano coatings to concrete surfaces. These treatments reduce the need for future cleaning by up to 50%, while preventing moisture intrusion, a key factor in extending the life of concrete in exposed environments.

Cleaning of energy installations

Cleaning powerlines

We offer inspection services using KTV Working Drone

Inspection services

Advanced drone inspection for the energy sector.

In the energy industry, inspection is just as critical as cleaning and surface protection. Corrosion, material fatigue, and structural degradation can severely impact performance, safety, and production efficiency.

KTV Working Drone delivers a complete inspection platform that combines visual, thermal, and 3D analysis for wind turbines, solar installations, and hydropower structures.

Our drone inspections provide verified data on:

- Cracks, corrosion, and surface degradation on steel, composite, or concrete elements.

- Delamination and blade erosion on wind turbines.

- Hotspots, shading, and damaged cells on solar panels.

- Leakage, moisture, and insulation failure in hydropower structures.

- Loose façade or panel elements that represent a potential fall hazard.

- Thermal losses and energy inefficiencies expressed in measurable kWh, CO₂, and financial impact.

Each inspection is interpreted by engineers to deliver accurate, actionable reports with clear recommendations for maintenance, safety, and energy optimization.

Wind turbines

Wind turbines are constantly exposed to harsh weather, vibration, and material stress.

Our drones can inspect rotor blades, towers, hubs, and nacelles without shutdown or rope access, identifying hidden cracks, delamination, corrosion, and oil leakage long before failure occurs.

By combining inspection, cleaning, and nano-surface treatment, we help clients:

- Extend turbine lifespan

- Prevent blade damage and ice formation

- Optimize output and safety performance

Solar installations

KTV Working Drone offers full thermal and visual inspection of solar farms and rooftop installations.

Our inspections detect hotspots, shading, inverter overheating, and glass damage, which can reduce production by up to 12% if not addressed.

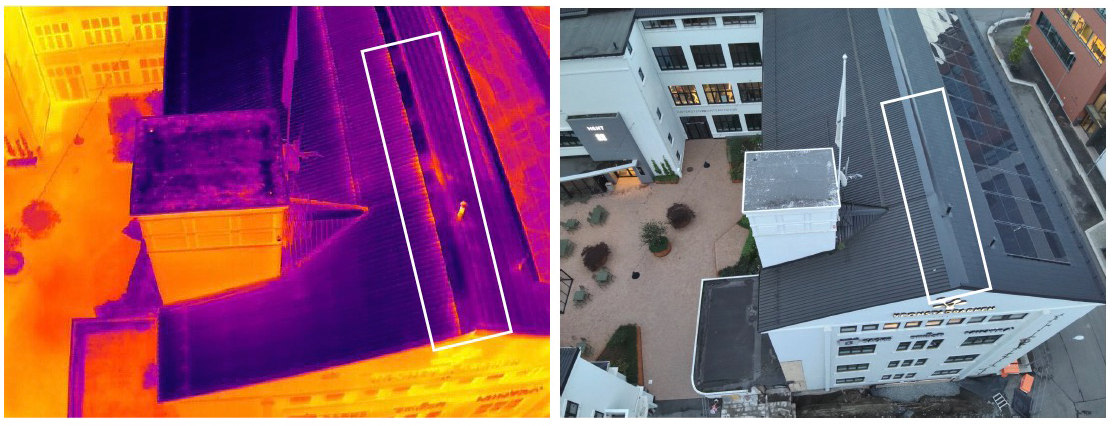

After cleaning, every site is analyzed using thermal imaging to verify energy flow and detect anomalies invisible to the eye. This ensures optimal yield and early detection of equipment wear or connection faults.

Hydropower and dams

Concrete infrastructure in hydropower facilities requires continuous inspection.

Our drones perform detailed visual and thermal scans of dam faces, spillways, tunnels, and retaining walls to identify cracks, water ingress, corrosion of reinforcement, and thermal bridging.

Each dataset is processed and reviewed by structural engineers to determine degradation trends and structural safety margins.

Surface treatment and sealing.

Following inspection, targeted surface treatment or sealing can be performed directly by drone, minimizing downtime and human exposure.

Drone-in-a-box solution

On-demand drone flights

For remote or large energy assets, KTV Working Drone provides a Dock System, drone-in-a-box solution.

This enables automated, scheduled, or event-triggered inspections for wind farms, solar parks, and hydropower installations.

The Dock allows for continuous area monitoring, incident response, and condition tracking, without manual deployment.

Contact us for more information or to discuss integration of a Dock system at your facility.

Sustainable, safe, and precise

All inspections are emission-free, cost-efficient, and deliver immediate insight into the condition of your energy assets.

With KTV Working Drone, you gain verified data, safer operations, and extended asset lifespan, ensuring maximum reliability and return on investment.

Protection of mineral surfaces.

We have developed a unique method for applying KTV NanoCoating after cleaning. The product creates a protective barrier that prevents water penetration and helps keep surfaces cleaner for longer. It has a lifespan of up to 10 years.

KTV NanoCoating is recommended for all mineral surfaces, including plaster, concrete, brick façades, and similar materials.

Thanks to our proprietary drone technology, we can apply the coating at a rate of up to 2,000 m² per hour. This makes it an ideal solution for use in the property, infrastructure, and energy sectors.

We are an experienced partner

KTV was founded in Norway in 1992, specializing in cleaning and surface treatment for the oil & gas, property, energy and infrastructure sectors.

KTV Working Drone was developed between 2015 and 2020 and is now established in 66 countries, delivering safe, efficient, and sustainable maintenance solutions to critical industries worldwide.

Contact us now!

KTV Working Drone delivers a comprehensive range of services, including facade and window cleaning, solar panel cleaning, infrastructure maintenance and cleaning, maintenance agreements as well as drone based inspections and 3D mapping.

Our drone technology removes the need for hazardous work methods, specialized access techniques, and complex safety procedures.

Please, feel free to send us a non-binding inquiry.